- Home

- Products

- Piston with Pilot Design Valves

-

Pilot Type Pressure Sustaining Valve

Piston with Pilot Design Valves

BTS / BFS

Pilot Type Pressure Sustaining Valve

Cast Iron ; Ductile Iron ; Bronze ; Stainless Steel

Thread 1½'' to 2'' ; Flange 1½” to 56''

0.3-4kgf/cm2 ; 2-8 kgf/cm2

NBR ; Viton

Addressing Overpressure: Protects Pipelines with Compact Conduit-Free Design

Model BTS / BFS, Pilot Operated Pressure Sustaining Valve(PSV), also known as Back Pressure Valve, or Back Pressure Sustaining Valve, is a valve that maintain required pressure of inlet port by opening only as much as required. It protects pipelines and equipment from damaging overpressure. Its Compact, Conduit-Free Design simplifies transportation, installation, and maintenance, while saving critical space in tight systems.

How does a Pilot Operated Pressure Sustaining Valve work?

A Back Pressure / Pressure Sustaining Valve is an automatic, pilot controlled valve that activated by the pressure of the pipeline. The valve will maintain a steady, predetermined pressure at the upstream of a pipeline.

The valve gate is normally closed. Gate will open once the upstream pressure exceeds the required set-point, thus reducing its upstream pressure. Gate will resume close position once upstream pressure falls below the set-point.

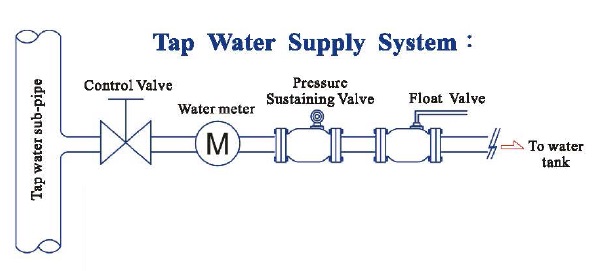

An illustration sketch of Pressure Sustaining Valve Installation

Key Features and Benefits of Pilot Operated Pressure Sustaining Valve

- No Conduit, Compact size for easy Transportation, Installation, Maintenance and Repair.

- Function to maintain a stable pressure in pipeline system.

- Convenient in-style mounts either horizontally or vertically.

- Wide range capacity to handle local water supply pressure and adjust to specific pump specifications.

- Adjusting pilot allows easy calibrated pressure adjustment.

- Easy maintenance, maintenance kits are available upon request.

What are the main advantages of pilot operated valves over diaphragm type valves?

- Higher flow capacity with larger chambers.

- Conduit-free, compact design.

- Wider size range (1½'' to 56'').

- Flexible horizontal or vertical installation.

- Durable materials: Cast Iron, Ductile Iron, Bronze, SS304 / SS316.

Frequently Asked Questions(FAQ) about Pilot Operated Pressure Sustaining Valve

Q1: Can Pilot Operated Pressure Sustaining Valves be installed vertically or horizontally?

Yes, they are designed for flexible installation in both horizontal and vertical orientations to fit different pipeline layouts.

Q2: How is maintenance performed on Pilot Operated Pressure Sustaining Valves?

Maintenance is straightforward. Regular inspection for leaks, cleaning, and replacement of worn seals or pistons is recommended. Maintenance kits are also available for easy servicing.

Related Products