- Home

- Products

- Direct Acting Design Valves

-

Titanium Pressure Reducing Valve

Direct Acting Design Valves

RDT-Ti

Titanium Pressure Reducing Valve

Titanium

Thread ½'' to 2''

1-5 kgf/cm2 ; 4-9 kgf/cm2

Viton ; Teflon

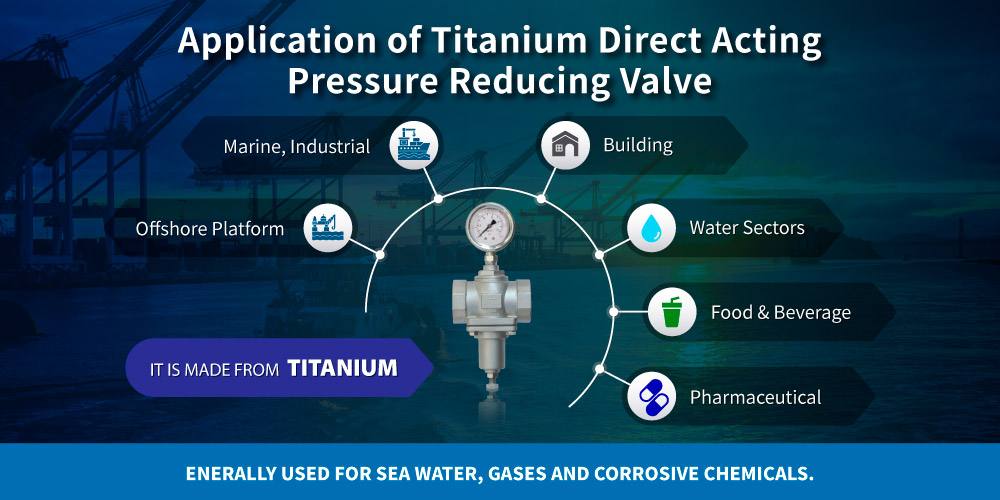

Engineered for the Extremes: Titanium Direct Acting PRV for Sea Water, Gases, and Corrosive Chemicals

Titanium is well known for its characteristics of lightness, strength, and high-corrosion-resistance. Model RDT-Ti are the direct acting pressure reducing valve that design and developed to sustain higher corrosive resistance for wider range of application.

Key Features and Benefits of Titanium Direct Acting Pressure Reducing Valve

- Corrosion resistance to chlorides, acids, and seawater.

- Lightweight and strong, reducing system load.

- Non-toxic and biocompatible, ideal for sensitive applications.

- Low maintenance, especially in harsh environments.

Frequently Asked Questions (FAQ) about Titanium Direct Acting Pressure Reducing Valve

Q1: Where are Titanium Direct Acting Pressure Reducing Valves typically used?

Titanium PRVs are commonly used in industries such as:

- Sea water or offshore industries.

- Desalination and water treatment.

- Chemical Processing (to handle corrosive fluids).

- Marine Engineering (to prevent rusting and ensure longevity in seawater).

- Pharmaceutical and Food Processing (where hygiene and corrosion resistance are critical).

Q2 : What should I do if the Titanium PRV is not maintaining the desired pressure?

Titanium PRVs are commonly used in industries such as:

- Check for Blockages: Debris or contaminants in the valve can cause malfunction.

- Inspect for Wear: Look for signs of wear on the spring or diaphragm, which may need replacement.

- Adjust the Pressure Setting: Ensure the adjustment screw is correctly set.

- Check System Conditions: Ensure there aren't any sudden changes in pressure or flow rate that could affect valve operation.

Related Products

X