- Home

- Products

- Piston with Pilot Design Valves

-

Pilot Type Pressure Relief Valve for Fire Protection

Piston with Pilot Design Valves

BTL / BFL

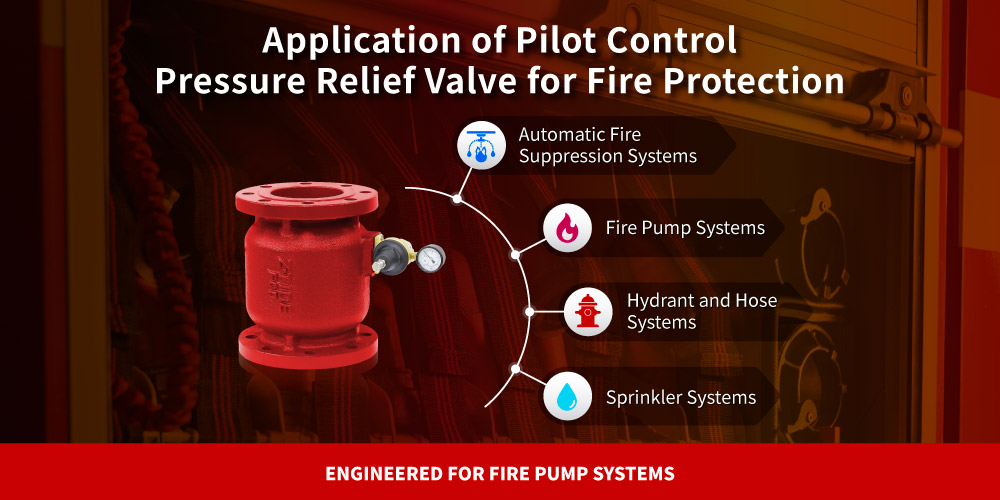

Pilot Type Pressure Relief Valve for Fire Protection

Cast Iron ; Ductile Iron ; Bronze ; Stainless Steel

Thread 1½'' to 2'' ; Flange 1½'' to 56''

0.3-4 kgf/cm2 ; 2-8 kgf/cm2 ; 5-13kgf/cm2

NBR ; Viton

Engineered for Fire Pump Systems to Maintain Pipeline Pressure Safety

Model BTL / BFL, Pilot Control Pressure Relief Valve maintain safe water supply pressure inside the pipe to prevent sudden increase of pressure that would damage the system by releasing exceeded pressure. Pressure Relief Valve is apply in Fire Protection Systems, specially Fire Pump system to maintain and protect system from over pressure.

Key Features and Benefits of Pilot Control Pressure Relief Valve for Fire Protection

- No Conduit, Compact size for easy Transportation, Installation, Maintenance and Repair.

- Releases pressure once pipeline pressure exceed set-pressure.

- Pressure Release valve is suitable for general liquids and gases.

- Convenient in-style mounts either horizontally or vertically.

- Wide range capacity to handle local water supply pressure and adjust to specific pump specifications.

- Adjusting pilot allows easy calibrated pressure adjustment.

- Easy maintenance, maintenance kits are available upon request.

How to adjust Pilot Control Pressure Relief Valve?

Step 1: Open upstream valve.

Step 2: Loose the lock nut of the controller adjustment screw and turn adjusting screw counterclockwise until lowest outlet pressure.

Step 3: Pressure Gauge on the valve indicate inlet pressure.

Step 4: Adjust the controller adjustment screw clockwise to the pressure required.

Step 5: Fasten up lock nut.

Why choose Z-Tide Pilot Control Pressure Relief Valve for Fire Protection?

- Reliable Overpressure Protection: Prevents system damage from sudden pressure surges during fire emergencies.

- Precise Pilot Control: Provides accurate, on-site adjustable set-points for stable and safe system operation.

- Flexible Installation: Designed for both horizontal and vertical layouts, suitable for diverse fire protection networks.

Project Reference: Pressure Relief Valve and Silent Check Valve for Firefighting System in Taiwan

In a fire pump system project in Taiwan, the client selected our pilot control pressure relief valve (Model BFL) to ensure safe and stable operation of the fire protection pipeline. This valve features a compact, no-conduit design, simplifying transportation, installation, and ongoing maintenance.

Designed specifically for fire protection systems—especially fire pump applications—this valve met the client's high standards for safety, responsiveness, and system integrity, demonstrating its reliable performance in a critical infrastructure environment.

Frequently Asked Questions(FAQ) about Pilot Control Pressure Relief Valve for Fire Protection

Q1: What is the function of a Pilot Control Pressure Relief Valve in fire protection systems?

Its main function is to release excess pressure from pipelines, pumps, and sprinkler systems, preventing overpressure that could damage equipment or compromise fire safety operations.

Q2: Why are Pilot Control Pressure Relief Valves for Fire Protection important in fire pump systems?

Fire pumps can generate sudden pressure surges during startup or flow fluctuations. The relief valve ensures safe operating pressure by instantly discharging excess pressure, protecting both the pump and connected fire protection equipment.

Q3: Can Pilot Control Pressure Relief Valve for Fire Protection be used with sprinkler and hydrant systems?

Yes. They maintain stable pressure for sprinkler networks and hydrant systems, ensuring reliable water flow during firefighting without damaging the piping or outlets.

Related Products